In the realm of modern interior design and architectural surfaces, printed quartz slabs have emerged as a game-changing solution. They blend the strength and durability of quartz with the limitless design possibilities enabled by advanced printing technologies. As consumer demand for customized stone surfaces grows across residential, commercial, and industrial sectors, the role of a printed quartz slab manufacturer becomes central to the creation of unique, personalized interiors.

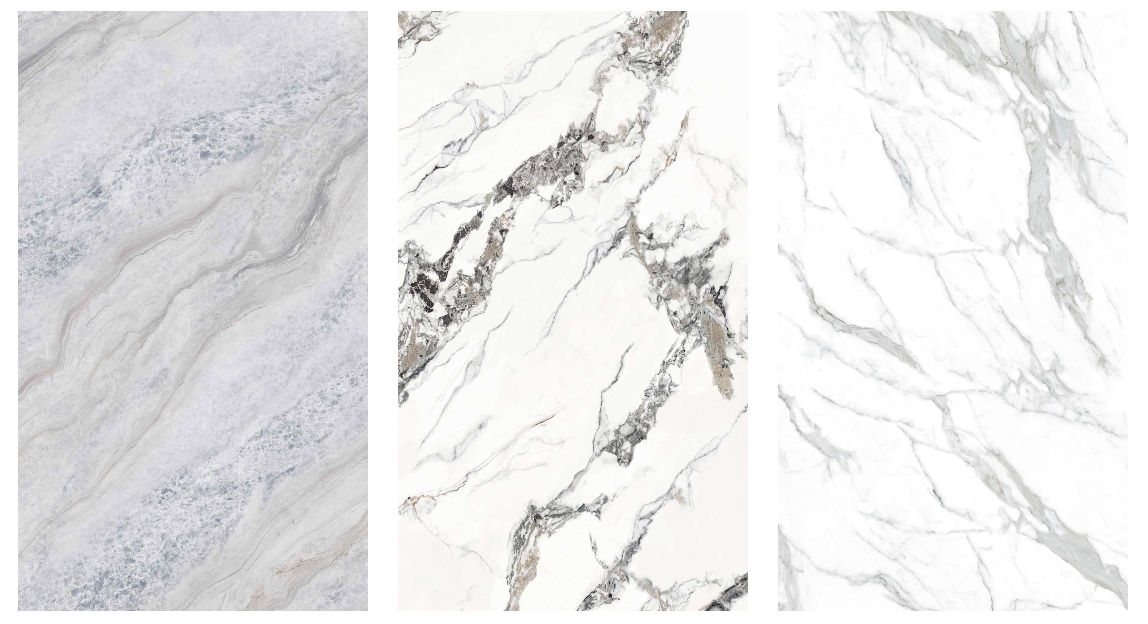

Printed quartz slabs are engineered stone products that combine natural quartz crystals with resins and pigments, which are then surface-printed using high-definition digital inkjet technology. This printing allows the replication of intricate patterns such as marble-like veins, natural wood grain, abstract designs, or even custom images onto the surface of the quartz slab. The result is a durable, low-maintenance, and visually striking surface.

Unlike traditional quartz surfaces that are limited by the pattern embedded during manufacturing, printed quartz surfaces offer unparalleled design freedom, making them ideal for bespoke interiors and custom surface projects.

The process begins with the production of a standard quartz slab. Here's how it typically unfolds:

Quartz Aggregation: Natural quartz particles are mixed with polyester resins and pigments.

Compaction and Curing: The mixture is poured into a mold, vibrated under vacuum, and cured at high temperatures to create a solid slab.

Surface Polishing: The surface is polished to a smooth, semi-gloss, or matte finish, depending on the requirement.

Digital Printing: Using high-definition UV inkjet printers, designs are printed directly onto the slab surface.

Surface Sealing: A protective UV-curable coating or nano-coating is applied to enhance durability, scratch resistance, and stain protection.

This technique allows a printed quartz slab supplier to create a broad range of custom visuals without compromising the slab's physical integrity.

There are several compelling reasons why designers, architects, and homeowners are turning to printed quartz:

Endless Design Possibilities: Printed quartz can replicate the aesthetic of natural stone such as Calacatta marble, onyx, or granite at a fraction of the cost and with greater consistency. It can also feature branding elements, artwork, or bespoke color palettes, offering clients a custom quartz surface that fits their exact design vision.

Durability and Low Maintenance: Quartz is inherently resistant to scratches, stains, and heat, making it an ideal material for high-traffic areas such as kitchen countertops, commercial worktops, hospitality interiors, and retail displays.

Eco-Friendly Options: Many manufacturers offer eco quartz slabs that include recycled materials and low-emission resins. These options are popular in LEED-certified buildings and sustainable construction.

Fast Turnaround for Custom Orders: Unlike natural stone, which can take weeks or months to source and fabricate, custom printed quartz can be produced rapidly once the design is finalized, making it ideal for project deadlines and commercial rollouts.

The versatility of printed quartz makes it suitable for a wide variety of applications:

● Kitchen Countertops

Printed quartz countertops offer homeowners the ability to combine personalized visuals with unmatched practicality. Popular options include marble-look quartz countertops and contemporary pattern quartz kitchen surfaces.

● Bathroom Vanities and Wall Cladding

Printed quartz adds elegance and moisture resistance to bathrooms, with patterns ranging from subtle stone to vibrant artistic prints.

● Commercial Interiors

Retail environments, hotel lobbies, and office reception areas benefit from the branding potential and luxury appeal of printed quartz. Logos and custom graphics can be seamlessly integrated into reception desks and feature walls.

● Furniture and Art Installations

Custom quartz can be used for tabletops, shelving, and even decorative panels in public art or boutique interiors.

As technology advances, printed quartz slab manufacturers are exploring new design horizons:

Hyper-realistic Stone Effects: Advancements in digital printing allow for near-perfect mimics of natural textures and 3D depth.

Large Format Quartz Panels: Oversized slabs reduce seams and open new doors in interior cladding and façade design.

Metallic and Matte Finishes: Surface finishes now range from ultra-glossy to soft matte or even metallic-infused designs.

Interactive Designs: Some printed surface manufacturers are experimenting with backlit designs, embedded LED panels, and smart quartz surfaces.

As consumers become more design-savvy and expect personalized interiors, the printed quartz slab industry is poised for continued growth. With evolving printing technologies, color durability, and surface treatments, printed quartz is no longer a niche product—it’s the next frontier in decorative surfaces.

Designers now have the tools to bring any vision to life, while manufacturers are innovating to make that process faster, more flexible, and sustainable.

With the growing popularity of printed quartz, selecting a reliable manufacturer is crucial. Here’s what to look for:

In-House Design Capabilities: A strong manufacturer will have a design team that can help translate concepts into print-ready formats.

Advanced Printing Technology: Look for manufacturers using UV inkjet systems, nano-coatings, and automated production lines to ensure color fastness and durability.

Customization Support: From digital mockups to prototype samples, a good custom quartz slab supplier will collaborate closely on design development.

Certifications and Quality Control: Ensure that the manufacturer adheres to international standards such as CE, NSF, or GREENGUARD.

Global Delivery and Support: If you’re an international contractor or interior firm, work with a printed quartz exporter with a proven logistics network.

As a trusted quartz stone manufacturer and supplier in China, we provide stylish and customizable printed quartz surfaces for both residential and commercial applications.

Our custom printed quartz is available in a wide range of patterns, textures, and color designs, making it ideal for quartz countertops, backsplashes, feature walls, and interior accents. Whether you're creating a bold statement or adding subtle decorative elements, our printed quartz surfaces bring creativity and durability together.

Choose Summerly Quartz custom printed quartz for artistic yet practical quartz surface solutions that elevate your interior projects.

Custom Quartz Slab Manufacturer and Supplier

The marriage of engineering precision and artistic freedom has made printed quartz slabs a leading choice in surface design. As demand for custom quartz countertops, digitally printed quartz wall panels, and personalized engineered stone slabs continues to grow, printed quartz will remain at the forefront of surface innovation. Whether you are a designer, homeowner, contractor, or stone fabricator, working with a trusted printed quartz slab manufacturer unlocks limitless opportunities to create unique, customized, and durable surfaces.

Browse our extensive collection of printed quartz slabs or contact Summerly Quartz for a custom solution.