Engineered quartz stone is a great choice for adding a pop of color and personality to your home. When used on walls, floors, countertops, and more, these quartz stones create a textured and dimensional look with their white patterns.

V035 Calacatta Marmo is a premium white engineered quartz stone featuring elegant grey veins, perfect for custom countertops, vanity tops, and interior surfaces.

|

Model Number |

V035 |

|

Material |

93% quartz sand and 7% resin |

|

Surface |

Polished/Leathered/Matte |

|

Package Type |

Fumigation Wooden Frame /Iron A Frame |

|

Warranty |

More than 5 years |

|

After-sale Service |

Online technical support |

Made from 93% natural quartz and 7% resin, this engineered quartz slab offers high durability, stain resistance, and easy maintenance, making it ideal for kitchen countertops, bathroom vanities, and commercial projects.

As a leading Calacatta white quartz slab manufacturer and supplier, Summerly Quartz provides wholesale quartz slabs with customized sizes and finishes to meet different project needs.

Our Calacatta quartz slabs offer the luxurious look of natural marble while maintaining the non-porous, scratch-resistant, and long-lasting properties of engineered quartz.

We supply custom quartz slabs in bulk for wholesalers, contractors, and designers, ensuring fast delivery and competitive prices. Contact Summerly Quartz today for high-quality quartz stone slabs wholesale and customized quartz surfaces.

The artificial quartz stone is flexible and its rich combination of colors gives it texture and a beautiful surface like the natural stone.

It can be widely used in public buildings (hotels, restaurants, banks, hospitals, exhibitions, laboratories, etc.) and home decoration (kitchen countertops, washstands, kitchen and bathroom walls, dining tables, coffee tables, window sills, door covers, etc.). It is a new environmentally friendly building interior decoration material that is free of radioactive pollution and can be reused.

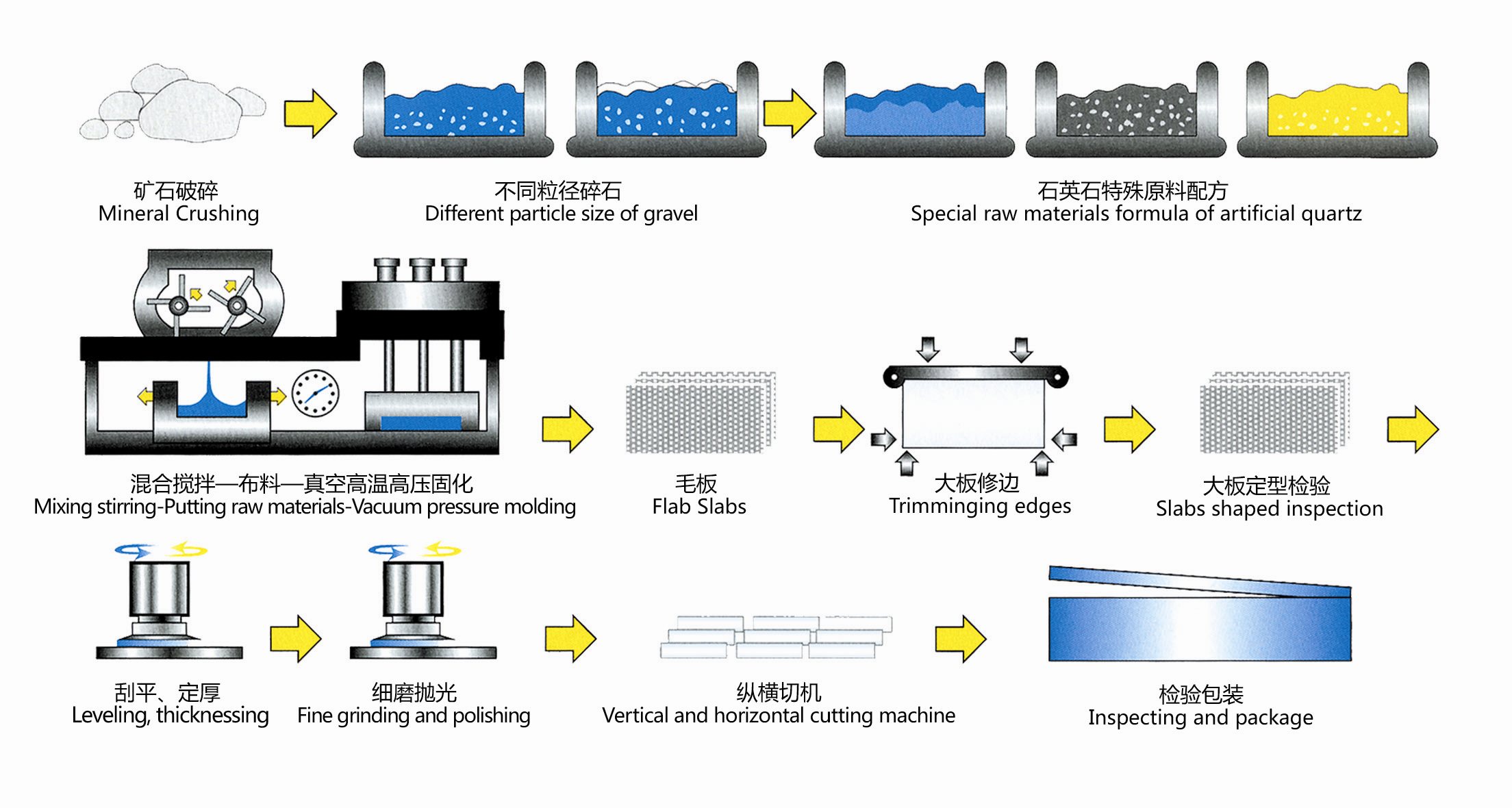

Mineral Crushing → Different particle size of gravel → Special raw materials formula of artificial quartz → Mixing stirring-Putting raw materials-Vacuum pressure molding → Flab Slabs → Trimminging edges → Slabs shaped inspection → Leveling, thicknessing → Fine grinding and polishing → Vertical and horizontal cutting machine → Inspecting and package

Artificial quartz stone, also known as engineered or synthetic quartz stone, is a man-made material created by combining 97% natural quartz crystals with 3% resin. The quartz crystals are grounded along with the resin and then pressed together to form slabs.

This quartz engineered stone is crafted to mimic the appearance and qualities of natural stones like granite or marble while enhancing its properties for various applications.

This quartz engineered stone is the best option for those who are looking for a low-maintenance and affordable countertop because the made-made stone has a lower price than the natural stone. Moreover, this engineered stone countertop, produced by SUMMERLY Quartz, is scratch-resistant, heat-resistant, non-toxic, and non-radioactive.

Thanks to the advanced manufacturing techniques, the artificial quartz stone countertop offers multiple benefits that the natural quartz stone can not offer:

Artificial quartz stone countertops are incredibly durable and resistant to scratches. Their robust surface can withstand the daily wear and tear of a bustling kitchen environment, maintaining a sleek and pristine appearance for years.

One of the standout features is their non-porous nature, which prevents the absorption of impurities, stains, or liquids. This characteristic ensures a hygienic surface, making it easy to clean and maintain.

These engineered quartz stone countertops exhibit exceptional heat resistance, making them suitable for kitchen use without the risk of damage from hot pots or pans. Moreover, they are non-toxic and free from any radioactive elements, ensuring safety in food preparation areas.

Their composition allows for easy processing and customization during installation. Whether it's cutting, shaping, or creating custom designs, these countertops offer flexibility in design and implementation.

With a wide range of colors and patterns available, artificial quartz stone countertops provide flexibility in design choices. Whether you prefer a classic, bold, or contemporary look, there's a color option to suit every aesthetic.

Its manufacturing process ensures stability, resulting in consistent quality across all countertops. This stability guarantees uniformity in terms of durability, appearance, and performance.

|

Test Item(s) |

Test Method (s) |

Test Result(S) |

|

Physical Properties |

||

|

Absorption by weight |

ASTM C97 |

0.03% |

|

Density |

ASTM C97/C97M-15 |

≥2.3gr/cm3 |

|

Flexural Strength |

TS EN 14617-2 |

40-65MPa |

|

ASTMC880/C880M-15 |

36-76 MPa |

|

|

Dimension Stability |

EN14617-12 |

Class A |

|

Stain, Chemical Resistance and Cleanability |

||

|

Stain Resistance Test (Polished) |

ANSI Z124.6-2007 |

Pass. Total Stain Resistance Value: 56 Maximum Individual depth of Staining: 0.04mm |

|

Chemical Resistance Test(Polished) |

ANSI Z124.6-2007 |

Pass,Unaffected |

|

Wear and Cleanability |

ANSI Z124.6 |

Pass |

|

Test Item(s) |

Test Method (s) |

Test Result(S) |

|

Durability |

||

|

Abrasive Resistance |

TS EN14617-4 |

29.0-36.0MM |

|

Mohs' Hardness (polished) |

EN101:1991 |

7 Mohs |

|

Freeze-Thaw Cycling |

ASTM1026 |

No Visual Damage |

|

Boiling Water Resistance |

ANSI NEMA LD3-3.5 |

No Effect |

|

High Temperature Resistance |

ANSI NEMA LD3-2005 |

No Effect |

|

Compressive Strength |

ASTM C170/C170M-15b |

Dry Condition: 234 MPa Wet Condition: 221MPa |

|

Impact Resistance |

EN14617-9 2005 |

5.02 J |

|

Reaction to Fire |

EN13501-1:2007 +A1: 2009 |

Bfl-S1 |

|

Thermal Shock Resistance |

ASTM -C484 |

No Visual Defects |

|

Boiling Water Resistance |

ANSI NEMA LD3-3.5 |

No Effect |

|

High Temperature Resistance |

ANSI NEMA LD3-2005 |

No Effect |