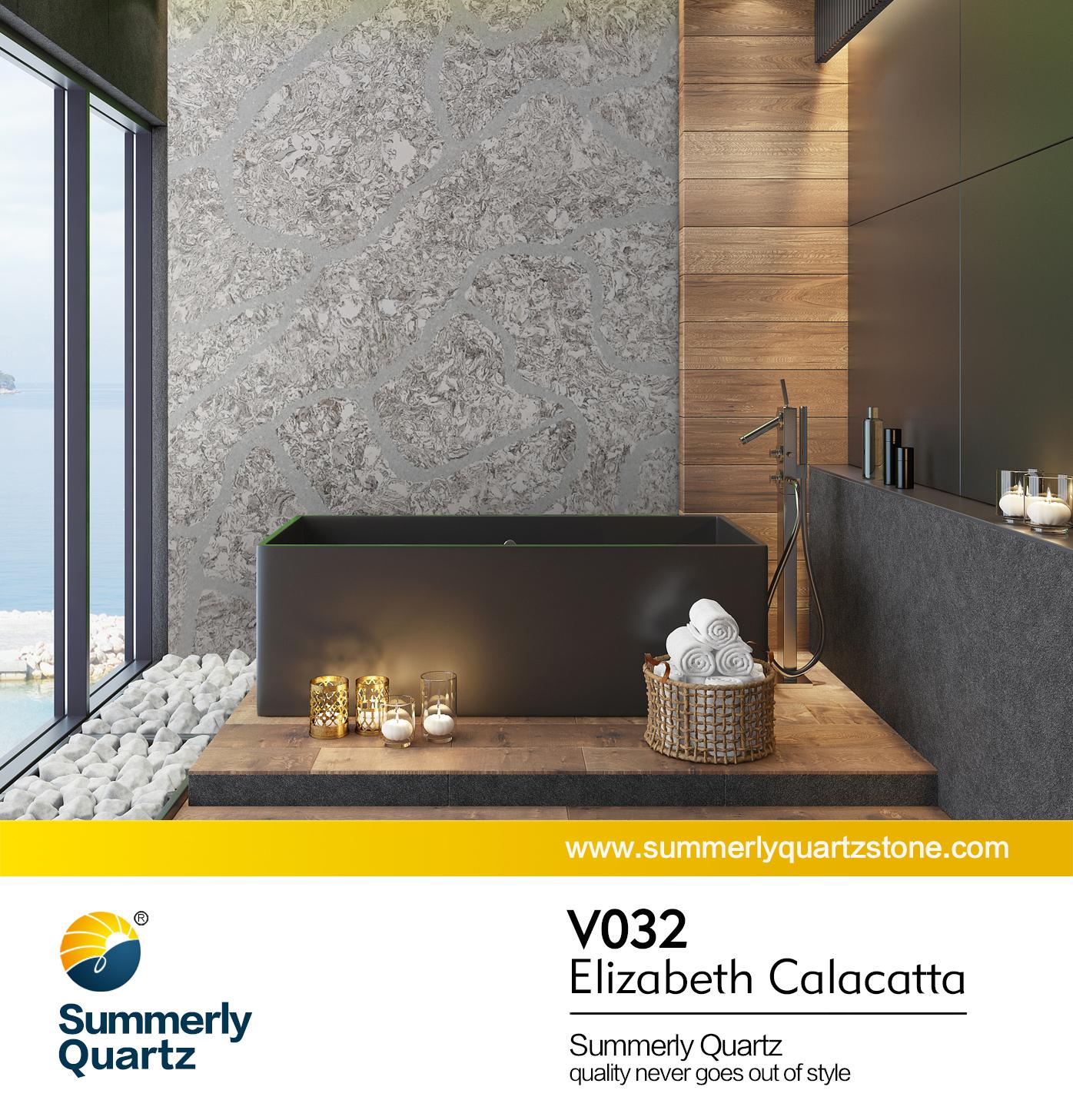

Engineered quartz stone is a great choice for adding a pop of color and personality to your home. When used on walls, floors, countertops, and more, these quartz stones create a textured and dimensional look with their white patterns.

|

Model Number |

V034 |

|

Material |

93% quartz sand and 7% resin |

|

Surface |

Polished/Leathered/Matte |

|

Package Type |

Fumigation Wooden Frame /Iron A Frame |

|

Warranty |

More than 5 years |

|

After-sale Service |

Online technical support |

The artificial quartz stone is flexible and its rich combination of colors gives itself with the texture and beautiful surface like the natural stone.

It can be widely used in public buildings (hotels, restaurants, banks, hospitals, exhibitions, laboratories, etc.) and home decoration (kitchen countertops, washstands, kitchen and bathroom walls, dining tables, coffee tables, window sills, door covers, etc.). It is an environmentally new building interior decoration material that is free of radioactive pollution and can be reused.

Quartz Engineered Stone: Packing

Two package methods are available in the Summerly Quartz ---- Fumigation Wooden Frame /Iron A Frame.

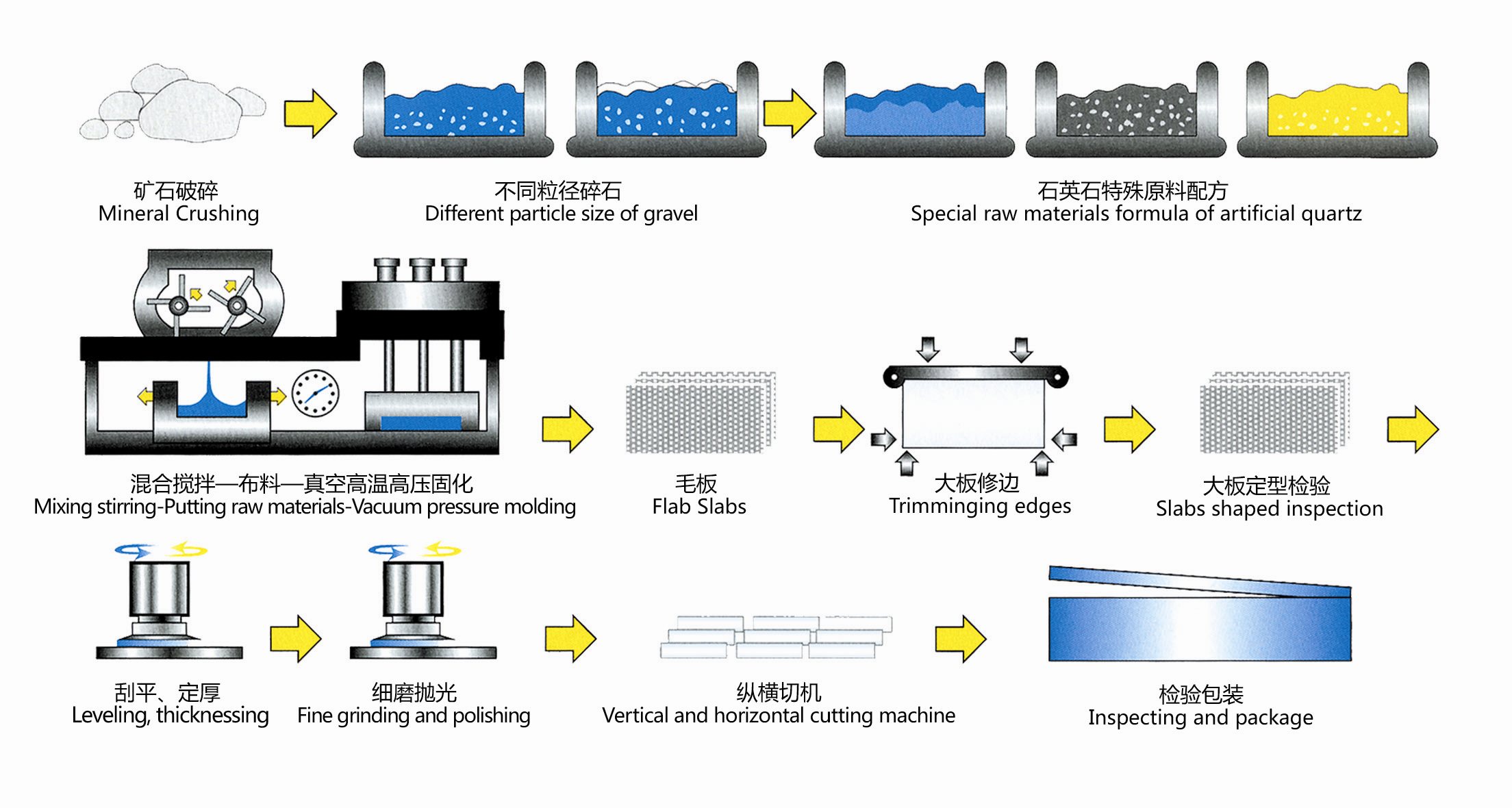

Quartz Engineered Stone: Production Process

Mineral Crushing → Different particle size of gravel → Special raw materials formula of artificial quartz → Mixing stirring-Putting raw materials-Vacuum pressure molding → Flab Slabs → Trimminging edges → Slabs shaped inspection → Leveling, thicknessing → Fine grinding and polishing → Vertical and horizontal cutting machine → Inspecting and package

|

Test Item(s) |

Test Method (s) |

Test Result(S) |

|

Physical Properties |

||

|

Absorption by weight |

ASTM C97 |

0.03% |

|

Density |

ASTM C97/C97M-15 |

≥2.3gr/cm3 |

|

Flexural Strength |

TS EN 14617-2 |

40-65MPa |

|

ASTMC880/C880M-15 |

36-76 MPa |

|

|

Dimension Stability |

EN14617-12 |

Class A |

|

Stain, Chemical Resistance and Cleanability |

||

|

Stain Resistance Test (Polished) |

ANSI Z124.6-2007 |

Pass. Total Stain Resistance Value: 56 Maximum Individual depth of Staining: 0.04mm |

|

Chemical Resistance Test(Polished) |

ANSI Z124.6-2007 |

Pass,Unaffected |

|

Wear and Cleanability |

ANSI Z124.6 |

Pass |

|

Test Item(s) |

Test Method (s) |

Test Result(S) |

|

Durability |

||

|

Abrasive Resistance |

TS EN14617-4 |

29.0-36.0MM |

|

Mohs' Hardness (polished) |

EN101:1991 |

7 Mohs |

|

Freeze-Thaw Cycling |

ASTM1026 |

No Visual Damage |

|

Boiling Water Resistance |

ANSI NEMA LD3-3.5 |

No Effect |

|

High Temperature Resistance |

ANSI NEMA LD3-2005 |

No Effect |

|

Compressive Strength |

ASTM C170/C170M-15b |

Dry Condition: 234 MPa Wet Condition: 221MPa |

|

Impact Resistance |

EN14617-9 2005 |

5.02 J |

|

Reaction to Fire |

EN13501-1:2007 +A1: 2009 |

Bfl-S1 |

|

Thermal Shock Resistance |

ASTM -C484 |

No Visual Defects |

|

Boiling Water Resistance |

ANSI NEMA LD3-3.5 |

No Effect |

|

High Temperature Resistance |

ANSI NEMA LD3-2005 |

No Effect |

Unveiling a fusion of elegance and resilience, the quartz engineered stone emerges as the epitome of sophistication in modern interior design. With its remarkable properties and captivating aesthetics, this versatile material transcends conventional boundaries, offering a world of possibilities to adorn your home with an unparalleled allure.

At just 0.03% absorption by weight, quartz engineered stone stands as a testament to durability, ensuring longevity and resilience against the trials of time. Boasting a density of ≥2.3gr/cm3 and a flexural strength ranging from 36 to 76 MPa, it promises not only a stunning visual appeal but also the structural integrity essential for enduring beauty.

The abrasive resistance of 29.0-36.0MM speaks volumes about its ability to withstand daily wear and tear, maintaining its pristine allure even in high-traffic areas. Polished to a gleaming 7 Mohs on the hardness scale, these engineered stones effortlessly marry aesthetic finesse with robust durability, offering a surface that withstands the test of time.

Imagine the canvas of your home coming to life with textured, dimensional white patterns adorning walls, floors, countertops, and more. The versatility of Quartz Engineered Stone not only adds a pop of vibrant color but also infuses your space with personality and charm, creating an ambiance that resonates with your unique style.

Moreover, its resilience extends beyond physical attributes. With a remarkable resistance to freeze-thaw cycling, it retains its visual splendor regardless of environmental challenges, ensuring that your investment in beauty remains pristine year after year.

From the understated elegance of a refined countertop to the grandeur of floor-to-ceiling installations, Quartz Engineered Stone stands as a beacon of sophistication, transforming your living spaces into a symphony of luxury and practicality.

Although quartz engineered stone contains the word “quartz”, the quartz engineered stone actually is a manufactured product composed of natural quartz particles and resin.

Summerly Quartz’s engineer stone typically contains 93% mineral quartz.

The quartz engineered stone is not easy to chip and scratch in normal use.