Quartz surfaces have become the cornerstone of modern interior design, offering durability, versatility, and unmatched aesthetics for kitchens, bathrooms, and commercial spaces. As the demand for high-quality engineered stone continues to grow, so does the number of quartz surface manufacturers striving to innovate and deliver products that meet evolving market expectations. In 2026, the competition among quartz surfaces companies has intensified, with factories across China, Europe, and the Americas leading the way in technology, sustainability, and design.

This article explores the 10 best quartz surface manufacturers in 2026, highlighting their innovation, production quality, and global reach. Beyond showcasing top manufacturers, we’ll also examine key trends in the quartz surfaces industry, the benefits of customized quartz products, and the crucial role of quartz surfaces distributors and suppliers in the international market.

Quartz surfaces, made from natural quartz mixed with resins and pigments, are renowned for their non-porous nature, scratch resistance, and ease of maintenance. Unlike natural stone, engineered quartz offers consistent coloring, durability, and design flexibility, making it a favorite choice among homeowners, designers, and builders.

In recent years, customization has become a driving force in consumer choices. The rise of quartz surfaces customized options allows clients to tailor dimensions, colors, and finishes to their exact project needs. This trend is pushing manufacturers to invest in new production technologies and flexible logistics systems.

To better understand the appeal of quartz, it's helpful to compare it to alternative surface materials such as granite, marble, laminate, and solid surface:

|

Feature |

Quartz |

Granite |

Marble |

Laminate |

Solid Surface |

|

Non-porous |

✅ |

❌ |

❌ |

✅ |

✅ |

|

Maintenance |

Low |

Medium |

High |

Low |

Low |

|

Design Flexibility |

High |

Medium |

Medium |

High |

Medium |

|

Stain Resistance |

High |

Medium |

Low |

Medium |

Medium |

|

Scratch Resistance |

High |

High |

Medium |

Low |

Medium |

|

Customization |

✅ |

❌ |

❌ |

✅ |

✅ |

As seen in the table above, quartz surfaces combine the best properties of natural and synthetic materials, giving quartz surfaces dealers a strong selling point in every segment of the market.

While quartz surfaces are widely known for their use in residential kitchens and bathrooms, their application has expanded across diverse industries. Many quartz surface suppliers are catering to commercial and industrial sectors due to quartz's strength, longevity, and hygienic properties.

Hospitality Sector: Hotels and resorts prefer quartz surfaces custom-made to match specific design themes. From reception desks to bathroom vanities and restaurant countertops, engineered quartz provides the elegant and durable surfaces these spaces demand.

Healthcare: The non-porous and antimicrobial properties of quartz make it an ideal material for clinics, hospitals, and laboratories. Quartz surfaces manufacturers are responding with specialized, hygienic slabs tailored to healthcare environments.

Retail and Commercial Interiors: Shopping malls, boutique stores, and office buildings utilize quartz for display counters, wall panels, and communal tables.

Educational Institutions: Universities and schools have begun to implement quartz surfaces customized for dormitories, libraries, and cafeterias, valuing their ease of cleaning and resistance to wear.

Selecting the right quartz surface is a crucial decision that impacts both the aesthetics and functionality of your space. When sourcing quartz slabs for commercial or residential projects, buyers—whether contractors, designers, or quartz surface distributors—should evaluate several key factors:

For projects requiring multiple slabs, such as full-height wall cladding or expansive countertops, consistency is key. Reputable suppliers will offer book-matched or lot-matched options to ensure seamless visual flow.

Choose from polished for a high-gloss, luxurious look, matte for a softer, contemporary feel, or leathered for a tactile, textured surface—ideal for feature walls or statement islands.

Standard thicknesses (12mm, 20mm, and 30mm) suit a range of applications, while custom-cut slabs cater to oversized islands, waterfall edges, or full wall installations, adding both drama and design flexibility.

Premium quartz surfaces offer high resistance to stains, scratches, impacts, and UV exposure. This makes them suitable for busy kitchens, high-traffic commercial areas, and even outdoor use.

Look for slabs certified by organizations like NSF, Greenguard, or CE—these ensure surfaces are food-safe, low in VOC emissions, and produced with environmental responsibility in mind.

Partnering with the right quartz surface manufacturer can significantly impact your project timeline, quality, and long-term satisfaction. Here’s what defines a top-tier quartz brand in today’s global market:

Industry leaders source high-purity quartz crystals, use state-of-the-art Italian or Bretonstone® technology, and maintain strict quality control at every stage—delivering surfaces that are not only beautiful but built to last.

Leading brands continuously update their collections with design-forward colors and patterns—from marble-look classics like Calacatta and Carrara to bold, contemporary styles with metallic veins or concrete finishes.

Top manufacturers invest in closed-loop water systems, solar-powered factories, and incorporate recycled materials, ensuring their products meet the rising demand for sustainable building materials.

Whether you’re in North America, Europe, Asia, or the Middle East, trusted quartz surface brands provide fast lead times, efficient logistics, and reliable after-sales support through their vast distributor and partner network.

From cut-to-size panels to exclusive color development for large-scale developments, premium brands offer bespoke solutions tailored to meet the design and performance needs of any project.

Here are ten manufacturers that are making waves in the global quartz surfaces market in 2026. These brands are recognized for their innovation, reliability, and market presence. This list is not ranked in a specific order.

Summerly Quartz is a rising star among quartz surface manufacturers in China, offering a comprehensive selection of slabs for kitchens, bathrooms, and flooring. The company is known for its dedication to quality and flexibility in meeting custom orders.

Summerly stands out in the quartz surfaces China market with its wide range of styles, including Calacatta, Carrara, marble-like, and modern fine-grain patterns. They serve both domestic and international clients through a strong network of quartz surfaces distributors and wholesalers.

Caesarstone is a globally recognized quartz surface producer, known for pioneering engineered stone since the early days of the industry. Their surfaces are celebrated for their durability and innovative aesthetics, often used in high-end residential and commercial projects.

The company works closely with architects and designers and continues to develop award-winning textures and styles. Their network of quartz surfaces dealers and distributors ensures worldwide availability.

Based in Spain, Cosentino is the parent company of Silestone, a flagship brand in the quartz surface space. Silestone is known for combining natural quartz with cutting-edge technology to deliver anti-bacterial, UV-resistant, and sustainable products.

Cosentino has a robust global supply chain, offering a wide range of quartz surfaces custom-made for clients in North America, Europe, Asia, and beyond.

Vicostone, headquartered in Vietnam, is one of the most innovative quartz surface manufacturers in Asia. Known for its state-of-the-art production lines and environmentally conscious processes, Vicostone has a strong foothold in global markets.

The brand is popular among quartz surfaces suppliers for its excellent consistency, quality control, and elegant design options that mimic natural stone.

HanStone Quartz is a well-regarded quartz surface manufacturer with operations in North America. Combining North American quality standards with Asian production efficiencies, HanStone delivers premium products that serve both residential and commercial sectors.

They offer strong support for quartz surfaces, customized orders, and have built a reputation for responsive customer service and reliable lead times.

Cambria is one of the few quartz surface producers that manufactures entirely in the United States. Known for high-quality, American-made products, Cambria emphasizes craftsmanship, innovation, and luxury design.

Their strong branding and vast collection of styles make them a top choice among designers and high-end builders looking for custom quartz surfaces and custom solutions.

Technistone is a European-based quartz surfaces company offering high-performance engineered stone surfaces. Their products are widely used in residential and commercial interiors across Europe and beyond.

With a commitment to environmental sustainability and premium aesthetics, Technistone is a trusted quartz surfaces supplier in the European market.

Viatera, produced by LG Hausys, blends advanced technology with beautiful design. LG’s global reputation for quality extends to its quartz surfaces factory operations, where innovation meets functional elegance.

Viatera offers a versatile catalog with styles that fit both traditional and contemporary spaces, and they are recognized for supporting large-scale quartz surface customized projects.

Baoliya Quartz is a major quartz surface manufacturer in China, offering durable and stylish quartz slabs to global clients. With a reputation for efficient logistics and a large product portfolio, Baoliya is a favorite among quartz surfaces dealers and project contractors.

They place a strong emphasis on precision fabrication and aesthetic appeal, helping customers achieve tailored designs for kitchen countertops, vanities, and more.

Compac, a Spanish quartz surfaces company, combines artistry with advanced engineering to create visually stunning and high-performance quartz products. With global distribution and a strong R&D foundation, Compac continues to push design boundaries.

They collaborate closely with architects and contractors, especially on quartz surfaces custom installations that demand unique colors, patterns, and finishes.

As we look deeper into the quartz surfaces market in 2026, several key trends are shaping how quartz surfaces manufacturers operate and innovate:

There’s a growing demand for sustainable materials in the construction and design industries. Top quartz surfaces factories are reducing emissions, recycling water, and incorporating post-consumer recycled materials into their slabs.

Today’s consumers are seeking more personalized designs. Whether it’s a hotel lobby or a luxury kitchen, quartz surfaces customized to fit specific color palettes, shapes, and sizes are in high demand. Manufacturers with flexible production capabilities are gaining a competitive edge.

With the rise of AI and automation, factories are enhancing precision and production speed. Digital design platforms also allow quartz surfaces dealers and wholesalers to preview and customize slabs in virtual showrooms.

Companies are building strong ties with quartz surfaces distributors across major markets, including North America, the Middle East, Southeast Asia, and Australia. This ensures faster delivery and better customer support for quartz surfaces suppliers and end-users.

Over the past decade, China has emerged as a global leader in quartz production. With a robust industrial base, competitive labor costs, and significant investments in technology, Chinese manufacturers now dominate the export market.

Leading quartz surfaces factories in China leverage automation, bulk raw material access, and skilled craftsmanship to produce high-quality slabs at scale. Moreover, quartz surfaces wholesalers in China offer flexible minimum order quantities (MOQs), appealing to both large contractors and boutique fabricators.

Additionally, Chinese suppliers often provide end-to-end support, including:

● OEM/ODM customization

● Global logistics coordination

For international buyers, partnering with a quartz surfaces China manufacturer ensures cost-efficiency without compromising on product quality.

Selecting the ideal quartz surface manufacturer is critical to the success of your project, whether you're working on luxury residential interiors, commercial developments, or large-scale hospitality spaces. When selecting a quartz surface manufacturer for your project, here’s what to look for:

Choose a manufacturer that offers a broad and up-to-date selection of colors, veining styles, and finishes—from timeless marble-looks to ultra-modern concrete and terrazzo patterns. A diverse portfolio ensures you can meet varying client preferences and design briefs.

For unique design requirements, opt for manufacturers that provide custom color development, cut-to-size options, edge profiling, and jumbo slab formats. This flexibility is especially important for bespoke residential builds or brand-specific commercial interiors.

Reputable manufacturers hold certifications like NSF (food safety), CE (European standards), ISO 9001 (quality management), and Greenguard (low emissions)—offering peace of mind on both safety and regulatory compliance.

For large or time-sensitive projects, production capacity matters. Partner with manufacturers that operate automated production lines and maintain strong inventory and fast lead times to avoid costly delays.

A professional customer service team that offers technical guidance, installation support, warranty services, and rapid issue resolution is essential for building long-term, trustworthy partnerships.

Looking beyond 2026, the quartz surfaces industry is poised for continued evolution. Several trends are likely to shape the next five years:

Manufacturers are experimenting with embedding wireless charging and touch-activated lighting within quartz countertops, turning static surfaces into functional tech interfaces.

As sustainability becomes non-negotiable, quartz surfaces producers are increasing the proportion of recycled glass, ceramics, and quartz in their slabs without sacrificing performance.

In commercial builds, modular quartz panels for walls, floors, and furniture are gaining popularity due to ease of installation and time savings.

More quartz surfaces wholesalers are embracing digital transformation, offering interactive catalogs, sample visualization tools, and real-time quotation systems online.

AI-driven design platforms may soon allow consumers and architects to generate custom patterns and simulate entire rooms in virtual environments before placing quartz surface orders.

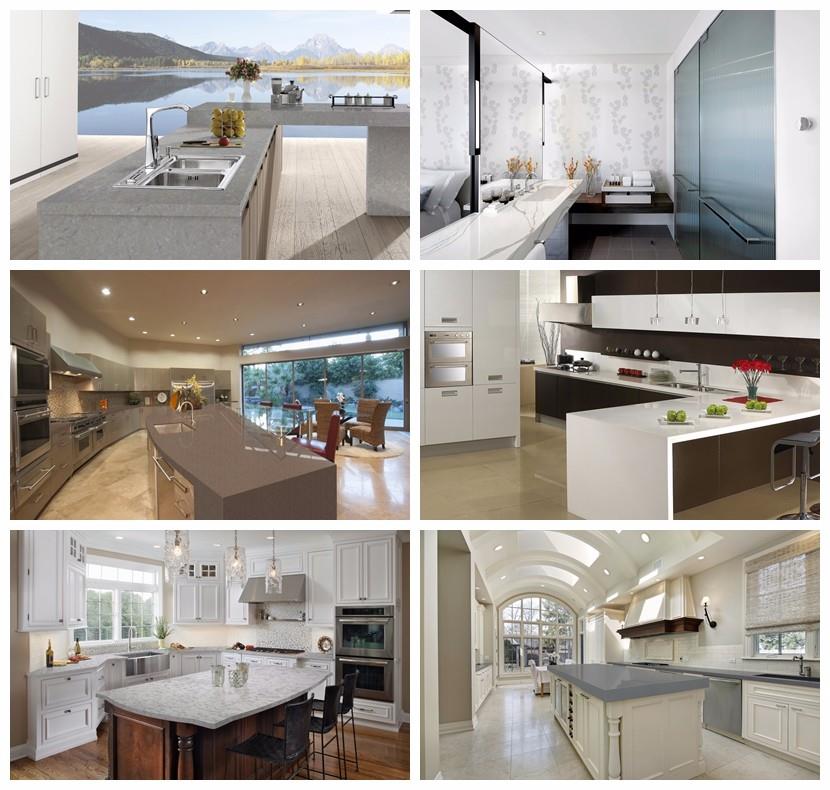

Different Colors Quartz Surface Manufacturer

Q: What are quartz surfaces made of?

A: Quartz surfaces are engineered stone slabs made from natural quartz crystals (usually over 90%) combined with resins, pigments, and additives. This combination creates a durable, non-porous surface ideal for countertops, walls, and flooring.

Q: Why choose quartz over natural stone like granite or marble?

A: Quartz offers better stain resistance, is non-porous (no sealing required), more uniform in appearance, and easier to maintain compared to natural stones like granite and marble.

Q: Is quartz environmentally friendly?

A: Engineered quartz is considered eco-friendly when made using recycled materials and sustainable manufacturing practices. Many manufacturers now offer slabs with recycled content and certifications like NSF or Greenguard.

Q: What is the average lifespan of a quartz countertop?

A: With proper care, quartz surfaces can last 20–30 years or longer, making them a long-term investment for both residential and commercial properties.

Q: What are the main applications of quartz surfaces?

A: Quartz surfaces are widely used for kitchen countertops, bathroom vanities, tabletops, wall cladding, flooring, and even in commercial environments like hotels, hospitals, and retail stores due to their durability and low maintenance.

Q: Are quartz surfaces heat resistant?

A: Quartz surfaces are heat-resistant to a certain degree, but they are not completely heatproof. It is advisable to use trivets or hot pads to avoid thermal shock or discoloration caused by placing hot cookware directly on the surface.

Q: What finishes are available for quartz surfaces?

A: Common finishes include polished, matte, and leathered. Polished is the most popular due to its glossy, reflective look, while matte and leathered finishes provide a more natural, textured aesthetic.

Q: How does the cost of quartz compare to granite or marble?

A: Quartz is often priced similarly or slightly higher than mid-range granite but typically less expensive than high-end marble. The benefit is in its low maintenance and long-term durability, offering better value over time.

Q: Can quartz surfaces be used outdoors?

A: Most standard quartz surfaces are not recommended for outdoor use as UV exposure can cause discoloration. However, some quartz surface manufacturers now offer UV-resistant quartz designed specifically for outdoor applications.

Q: What thickness options are available for quartz slabs?

A: Common thicknesses include 12mm, 15mm, 20mm, and 30mm. Thicker slabs are typically used for countertops, while thinner ones can be used for wall cladding or lightweight furniture applications.

Q: Do quartz surfaces require sealing like granite?

A: No, one of the main benefits of quartz is that it is non-porous and does not require sealing. It resists stains and bacteria better than porous natural stones.

Q: What are the benefits of buying from a quartz surfaces wholesaler or distributor?

A: Working with a quartz surface wholesaler or distributor allows bulk purchasing, better pricing, consistent inventory, and access to new collections and exclusive designs. It’s ideal for construction companies, retailers, and contractors.

Q: Who are the top quartz surface manufacturers in 2026?

A: Some of the top global quartz surface manufacturers in 2026 include well-known international brands and trusted suppliers from China. While the article lists 10 top picks, it's always important to verify supplier capabilities based on your region and project needs.

Q: Can I customize quartz surface patterns and sizes?

A: Yes, many quartz surface manufacturers offer custom designs, finishes, edge profiles, and slab sizes to meet specific project requirements for both residential and commercial use.

Q: Are Chinese quartz surface factories reliable?

A: Yes, many quartz surface factories in China have advanced production facilities, offer global shipping, and comply with international quality standards. Always request samples and certifications when sourcing.

Q: How do I choose the right quartz surface supplier or distributor?

A: Look for suppliers with strong references, customization options, quality control processes, competitive pricing, and responsive customer service. It's also beneficial to work with local quartz surface dealers for logistics and installation support.

Q: How is quartz surface quality evaluated?

A: Quality is assessed based on factors like quartz content, uniformity of pattern, resistance to stains and scratches, polishing consistency, and certifications (such as ISO, NSF, CE). Trusted manufacturers usually provide product testing data.

Q: How can I import quartz surfaces from China?

A: To import from a quartz surfaces factory in China, you need to identify a reliable supplier, confirm product specs, request samples, negotiate shipping and payment terms (usually FOB or CIF), and ensure import compliance with your country’s regulations.

Quartz Surface Manufacturer in China - Summerly Quartz

Quartz surfaces continue to dominate the global construction and interior design industries. The top manufacturers are not just focused on volume but are also investing in aesthetics, sustainability, and client-centered services. Whether you're a contractor, interior designer, or distributor, working with a reliable quartz surfaces company is essential to delivering quality results.

From globally renowned names like Caesarstone and Silestone to rising manufacturers in the quartz surfaces China market, such as Summerly Quartz, the industry is rich with innovation and opportunity. As demand grows for quartz surfaces customized solutions, the importance of choosing the right quartz surface wholesaler, producer, or dealer has never been greater.

Whether your project calls for timeless elegance, cutting-edge design, or functional performance, the top quartz surface manufacturers are ready to deliver.